Pulsed Laser Deposition (PLD)

Adnanotek's PLD systems provide deposition of a wide range of materials with monolayer accuracy.

Entire deposition process is controlled by industrial computer and fully automatic.

Important process parameters set by operator could be visible and controlled in real time.

Applications of our PLD systems are mostly focused on quantum devices fabrication.

Entire deposition process is controlled by industrial computer and fully automatic.

Important process parameters set by operator could be visible and controlled in real time.

Applications of our PLD systems are mostly focused on quantum devices fabrication.

Categories

Menu

PLD - 12L

( High End )

Pulsed Laser Deposition (PLD)

PLD - 18L

(Very High End)

Pulsed Laser Deposition (PLD)

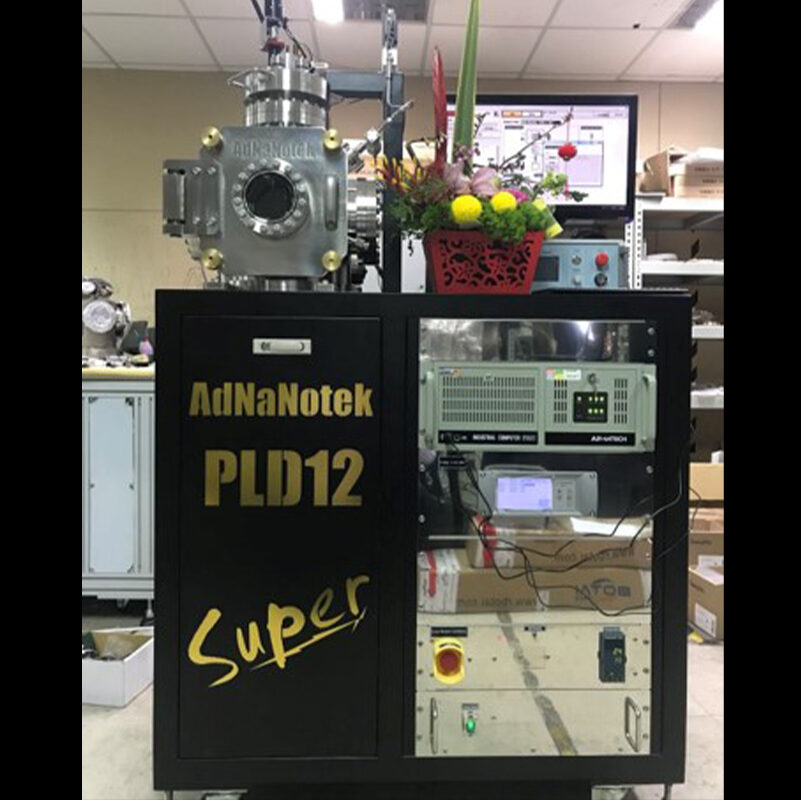

PLD - Super

(Single Chamber)

Pulsed Laser Deposition (PLD)

This Linear transfer system include one PLD system and UHV sputter, sample could transfer from one to other chamber through magnet arm.

Totally UHV condition and easy access subtracts.

Sputter equip up to 6 cathodes and laser heater heating up to 1000 degree C.

PLD easy upgrade to Laser MBE by any high pressure RHEED from RHEED supplier.

Totally UHV condition and easy access subtracts.

Sputter equip up to 6 cathodes and laser heater heating up to 1000 degree C.

PLD easy upgrade to Laser MBE by any high pressure RHEED from RHEED supplier.

Advantages

- Can work in reactive gas environment (e.g. oxygen- or nitrogen-rich environment)

- Versatile method (any material)

- Congruent evaporation

- High deposition rates

- Clean process

- Plume at high energy

- Broad range of gas pressures Φ

- Very slow growth rate

- Any material possible deposition

- Multi material mixing ratio

- Super conductor material, Quantum

Laser Heating Manipulator

AdNaNoTek's Laser heating system is developed as a perfect solution for heating your sample in oxygen- and nitrogen-rich atmosphere and is UHV compatible.

AdNaNoTek’s Laser Heater can heat the substrate with well focus beam, such that, only the targeted area will be heated.

The mechanism with a small distance from the plate stay at a relatively low temperature, reducing the outgassing from nearby surfaces.

In addition, the system's support tube remains cool even after 10 hours of operation.

AdNaNoTek’s Laser Heater can heat the substrate with well focus beam, such that, only the targeted area will be heated.

The mechanism with a small distance from the plate stay at a relatively low temperature, reducing the outgassing from nearby surfaces.

In addition, the system's support tube remains cool even after 10 hours of operation.

** Adnano-tek RHEED Screen Set

This RHEED screen is shield protected; it can block primary electron beam and avoid this strong e-beam damage phosphorus screen

Due to the high pressure of condition; sometimes the electron beam is diffused and looks fuzzy.

Our screen design is capible extended closed to sample or far away from substrate.

Our screen design is capible extended closed to sample or far away from substrate.

** Target Replacement Under Vacuum

In a traditional PLD system, every time the target material ran out, the system must be vented to air for target replacement, however by doing so, the process parameters and the cleanliness of the system environment will be affected.

AdNaNoTek’s PLD system provides a way to replace the target in UHV condition, so we can maintain the system's cleanliness and process parameters.

AdNaNoTek’s PLD system provides a way to replace the target in UHV condition, so we can maintain the system's cleanliness and process parameters.

Pulsed Laser Deposition System PLD / Laser MBE

Pulse Laser Scanning in X and Y high speed scan large target laser rastering scan

Wish deposit large size wafer with nice uniformity.

Here is answer! With High speed scanning system ; Adnano-tek PLD-18L become industrial PLD, It can deposit large size wafer up to 8 inch.

With this benefit, customer safe valiable target, and Excellent uniformity

Here is answer! With High speed scanning system ; Adnano-tek PLD-18L become industrial PLD, It can deposit large size wafer up to 8 inch.

With this benefit, customer safe valiable target, and Excellent uniformity

Pulsed Laser Deposition (Laser MBE or PLD) can deposit thin-film with extremely high quality and great repeatability.

This special system is equipped with a planetary target holder with maximum of 6(9) targets.

This allows the target manipulator to revolve and rotate.

The revolution allows selection of different sample targets, and the rotation (together with the sweep mechanism) allows improvement in the efficiency of the target material for thin film deposition.

The mask system allows formation of unique deposition pattern on the thin film.

The target position can also be adjusted up and down to optimize target to substrate distance.

It is designed to allow, in-vacuum target exchange.

PLD can adapt different design depending on researcher's need: It can be designed with multi-functional coating tool extension compatibility, which allows the system to be installed with a variety of deposition components, such as effusion cells, magnetron sputtering source, e-beam evaporators, etc; or it can designed to have minimal footprint and compact structure for flexible mobility, which allows researchers to easily arrange the position and/or transfer the equipment with ease.

This special system is equipped with a planetary target holder with maximum of 6(9) targets.

This allows the target manipulator to revolve and rotate.

The revolution allows selection of different sample targets, and the rotation (together with the sweep mechanism) allows improvement in the efficiency of the target material for thin film deposition.

The mask system allows formation of unique deposition pattern on the thin film.

The target position can also be adjusted up and down to optimize target to substrate distance.

It is designed to allow, in-vacuum target exchange.

PLD can adapt different design depending on researcher's need: It can be designed with multi-functional coating tool extension compatibility, which allows the system to be installed with a variety of deposition components, such as effusion cells, magnetron sputtering source, e-beam evaporators, etc; or it can designed to have minimal footprint and compact structure for flexible mobility, which allows researchers to easily arrange the position and/or transfer the equipment with ease.

PLD is also installed with laser heating manipulator which is the perfect heater especially for oxygen-rich or any atmospheric conditions.

It provides a highly localize heating mechanism that can easily heat up the substrate up to 1200°C (at E-3 torr and below), hence maintaining the nearby components at a low temperature to avoid substrate contamination due to out-gassing.

In addition, precise control and high stability is achieved by making the process automated with the use of the FBBEAR control software. The FBBEAR control software, provides complete data logging, precise parameter tuning which allows user to have easy operation and reliable experimental repeatability.

PLD (Laser MBE) can be applied for thin layer deposition of materials like: Heterostructure metal oxides (e.g. Fe/SrTiO3, Nb/SrTiO3, BiFeO3, etc), high temperature superconducting materials, silicon oxides, high k oxides, metal nitrides, ferroelectric materials, etc.

It provides a highly localize heating mechanism that can easily heat up the substrate up to 1200°C (at E-3 torr and below), hence maintaining the nearby components at a low temperature to avoid substrate contamination due to out-gassing.

In addition, precise control and high stability is achieved by making the process automated with the use of the FBBEAR control software. The FBBEAR control software, provides complete data logging, precise parameter tuning which allows user to have easy operation and reliable experimental repeatability.

PLD (Laser MBE) can be applied for thin layer deposition of materials like: Heterostructure metal oxides (e.g. Fe/SrTiO3, Nb/SrTiO3, BiFeO3, etc), high temperature superconducting materials, silicon oxides, high k oxides, metal nitrides, ferroelectric materials, etc.

In Pulsed-Laser Deposition (PLD), high power pulsed laser beam is focused on the surface of the target.

When the laser pulse is absorbed by the target, energy is converted to electronic excitation and then into thermal, chemical and mechanical energy.

This results in rapid evaporation or ablation of the target which produces a luminous plasma plume.

The plume which contains the ablated target material will rapidly expand into the surrounding vacuum and then condenses into a thin-layer film on the substrate.

When the laser pulse is absorbed by the target, energy is converted to electronic excitation and then into thermal, chemical and mechanical energy.

This results in rapid evaporation or ablation of the target which produces a luminous plasma plume.

The plume which contains the ablated target material will rapidly expand into the surrounding vacuum and then condenses into a thin-layer film on the substrate.

In order to achieve a single atomic layer coating in PLD, UHV condition should be maintained; and precise control of thin-layer deposition parameters is required.

AdNANoTek's PLD System with its built-in system control software is developed to achieve the above mentioned criteria.

AdNaNoTek's PLD System is also equipped with Reflective High Energy Electron Diffraction (RHEED) and RHEED monitoring software.

The RHEED system provides real-time monitoring and analysis of the epitaxial growth process like a) counting of the growth of individual atomic layers, and b) determination of the growth mechanism (i.e. epitaxial growth, step flow growth, or three dimensional island growth).

This technique permits the growth of high quality thin films and superlattices of perovskite structured materials with atomic layer precision.

The RHEED system provides real-time monitoring and analysis of the epitaxial growth process like a) counting of the growth of individual atomic layers, and b) determination of the growth mechanism (i.e. epitaxial growth, step flow growth, or three dimensional island growth).

This technique permits the growth of high quality thin films and superlattices of perovskite structured materials with atomic layer precision.