We Don't Sell, We Solve.

E-Beam Evaporation

E-beam evaporator is a versatile multisource deposition tool which allows deposition a wide range of materials like

- High-k dielectrics: HfO2, ZrO2, Al2O3, Sc2O3 and others

- Metals: Al, Cu, Ta, Ni, Ag, Au, Ti and others

- Elemental semiconductors: Si and Ge Depending on customer application we provide EBS and JEB series E-beam evaporators.

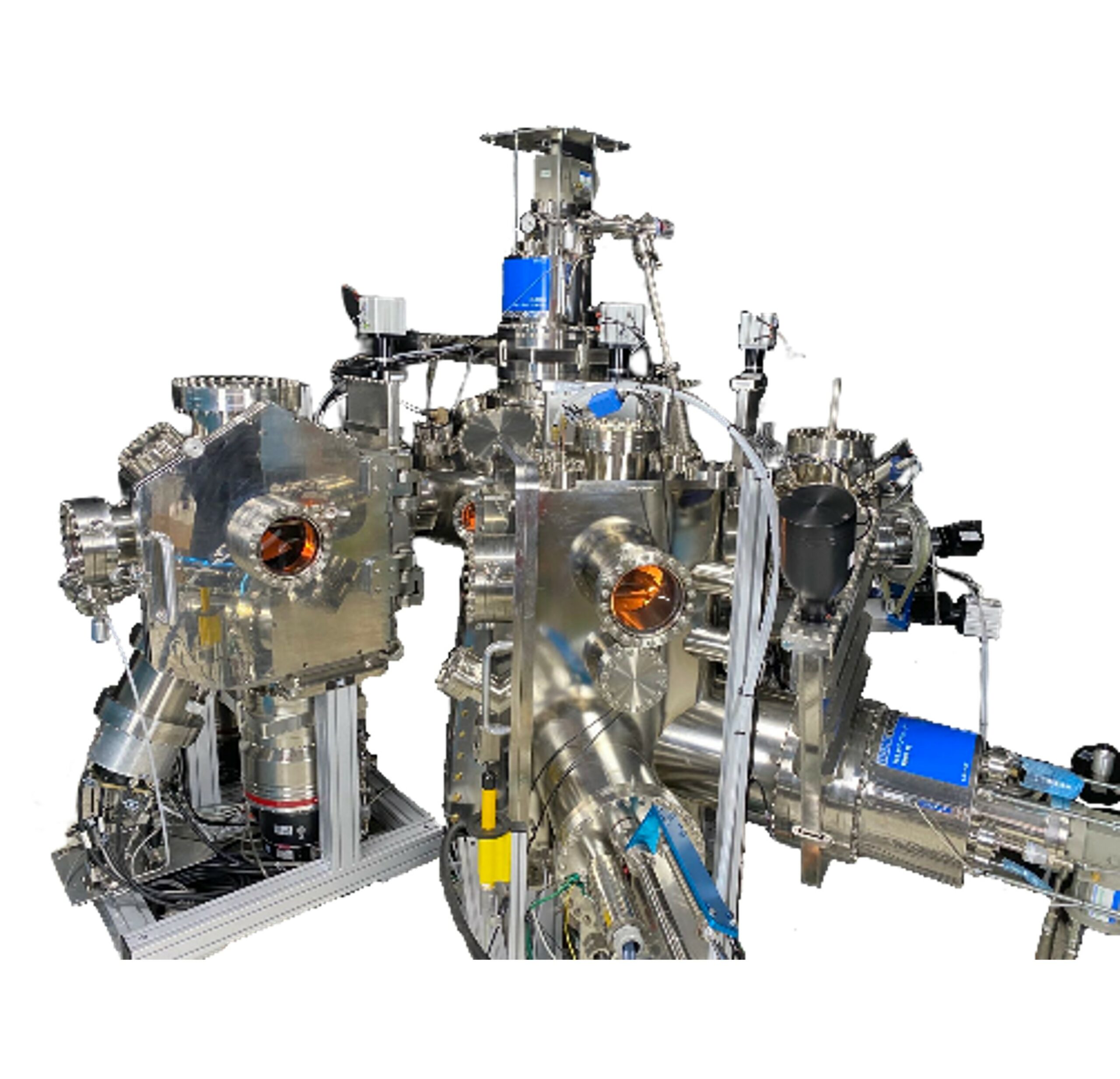

Molecular Beam Epitaxy

MBE systems are easy to use with a design configurable for III-V and II-VI emerging materials, including applications that require the integration with e-beam technology.

Semiconductor, metal, dielectrics, organics, etc…

- Semiconductor, metal, dielectrics, organics, etc...

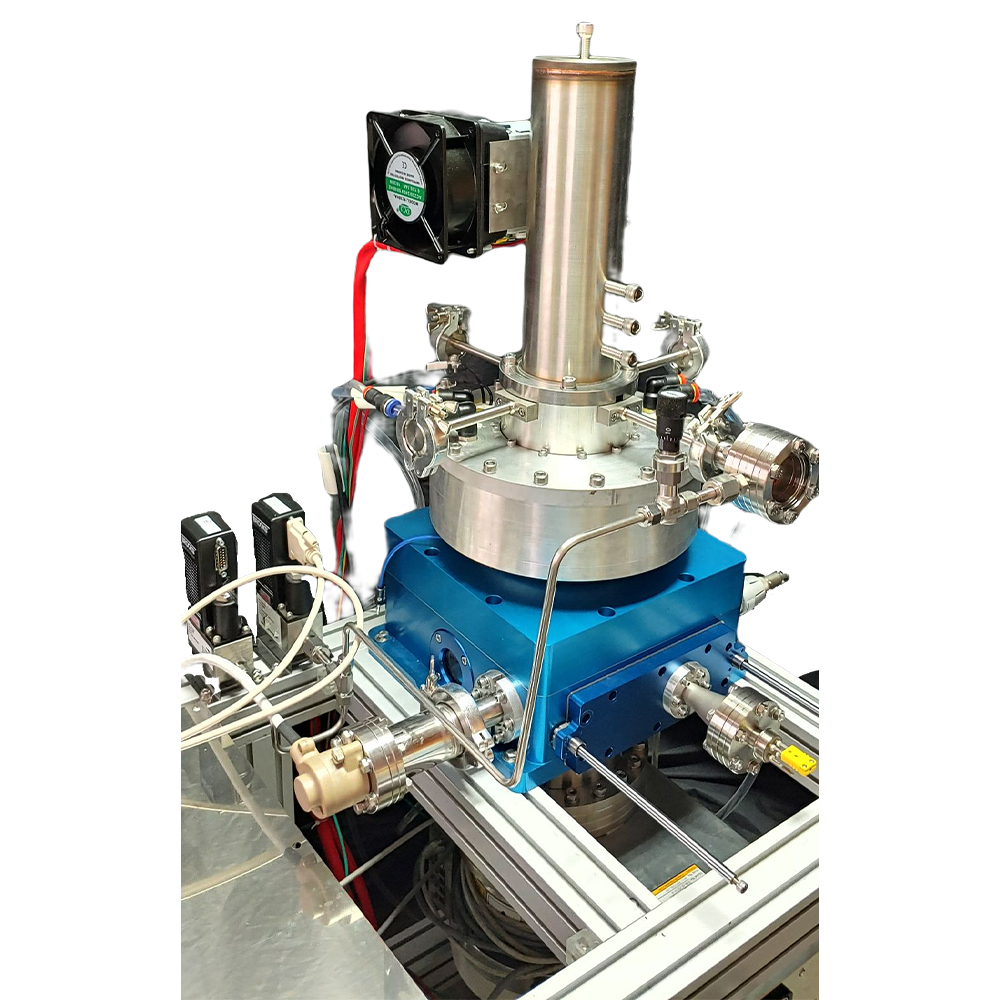

Magnetron Sputter

Depending on customer application DC or RF magnetron sources could be installed with substrate holder up to 8”.

Substrate temperature could be achieved up to 800 oC with resistance heater.

Laser substrate heater is available as an option.

Pulsed Laser Deposition System

Also called Laser MBE systems

PLD is another versatile widespread technique which is used for deposition metal oxides and multi combination materials.

We provides PLD tools with different number of targets and Oxide Semiconductor, metal, etc…

Thermal Evaporator System

Thermal Evaporator is another versatile widespread technique which is used for metal deposition and multi combination low temperature materials.

We provides thermal evaporator tools with different number of metal, etc…

Ion Beam Sputtering Deposition

Also called IBSD systems

IBD is versatile widespread technique which is used for deposition metal oxides and multi combination materials.

We provides IBD tools with different number metal and Oxide Semiconductor, etc…

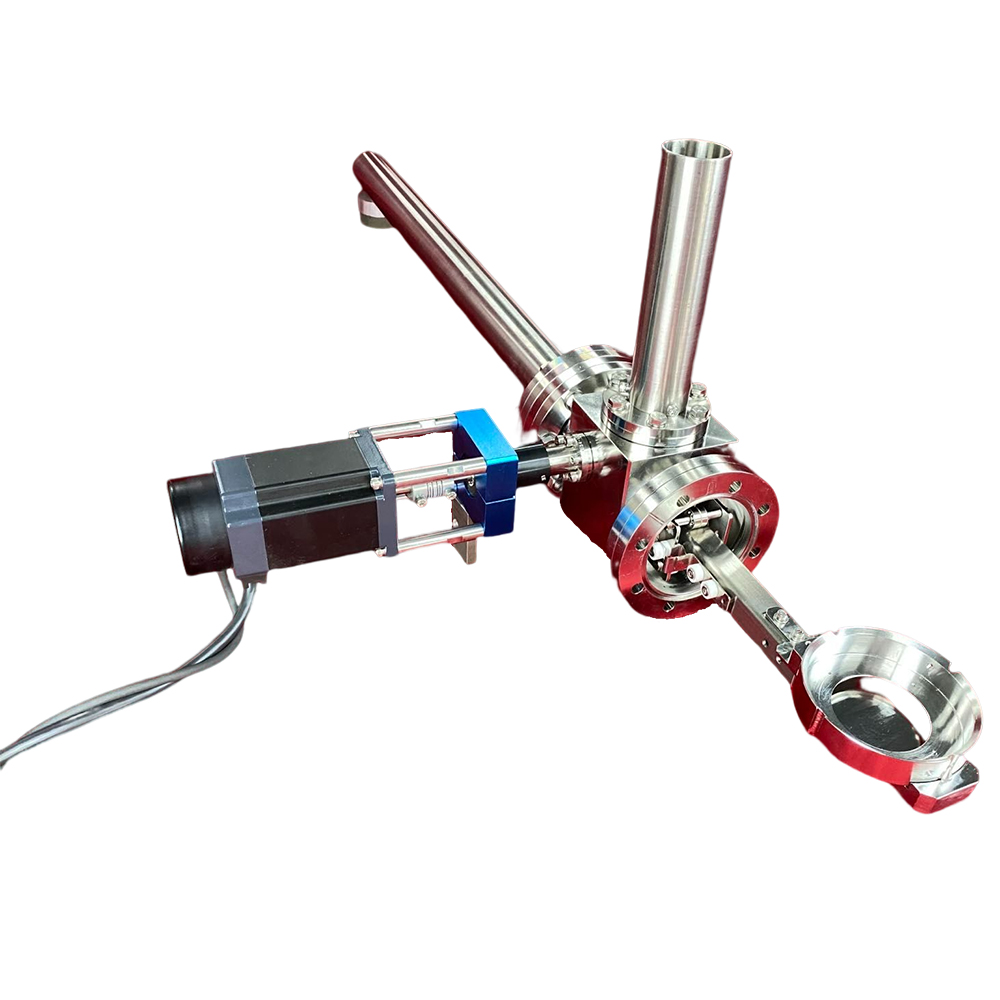

Quantum Computing Deposition System

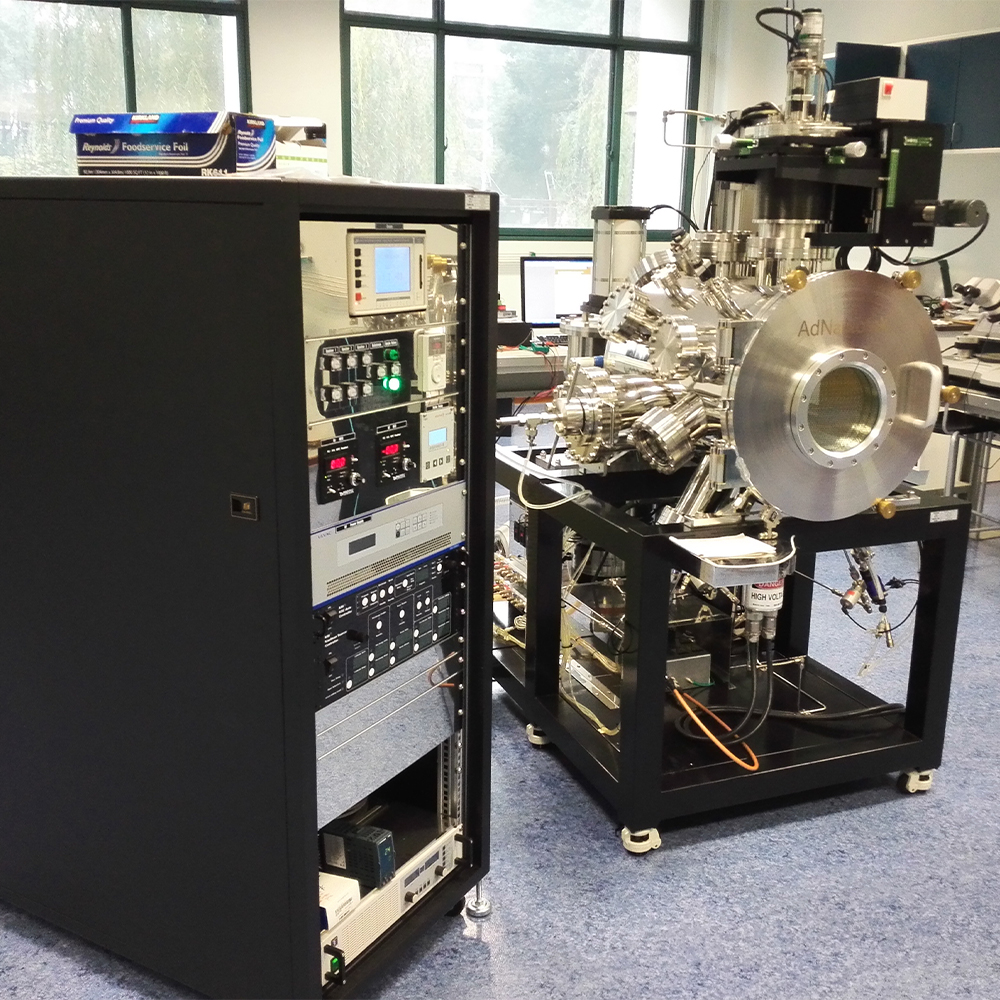

Josephson Junction Electron Beam Evaporator (JEB) Cluster is one of AdNaNoTek’s specialized deposition system that is dedicated to create Josephson junction for quantum computing devices and applications.

- JEB-2, 3, 4 and cluster system available

RIE System

RIE is belongs to dry etching, it used chemically reactive plasma to remove deposition coating layer on substrate.

ICP-RIE System

ICP-RIE is belongs to dry etching, it used chemically reactive plasma to remove deposition coating layer on substrate. It has upper plasma coil and substrate RF sample bias.

ECR-RIE System

ECR-RIE is belongs to dry etching, it used microwave and electro magnet to make chemically reactive plasma to remove deposition coating layer on substrate.

IBE System

IBE is belongs to dry etching, it used ion source to make chemically reactive neutral particles to remove deposition coating layer on substrate.

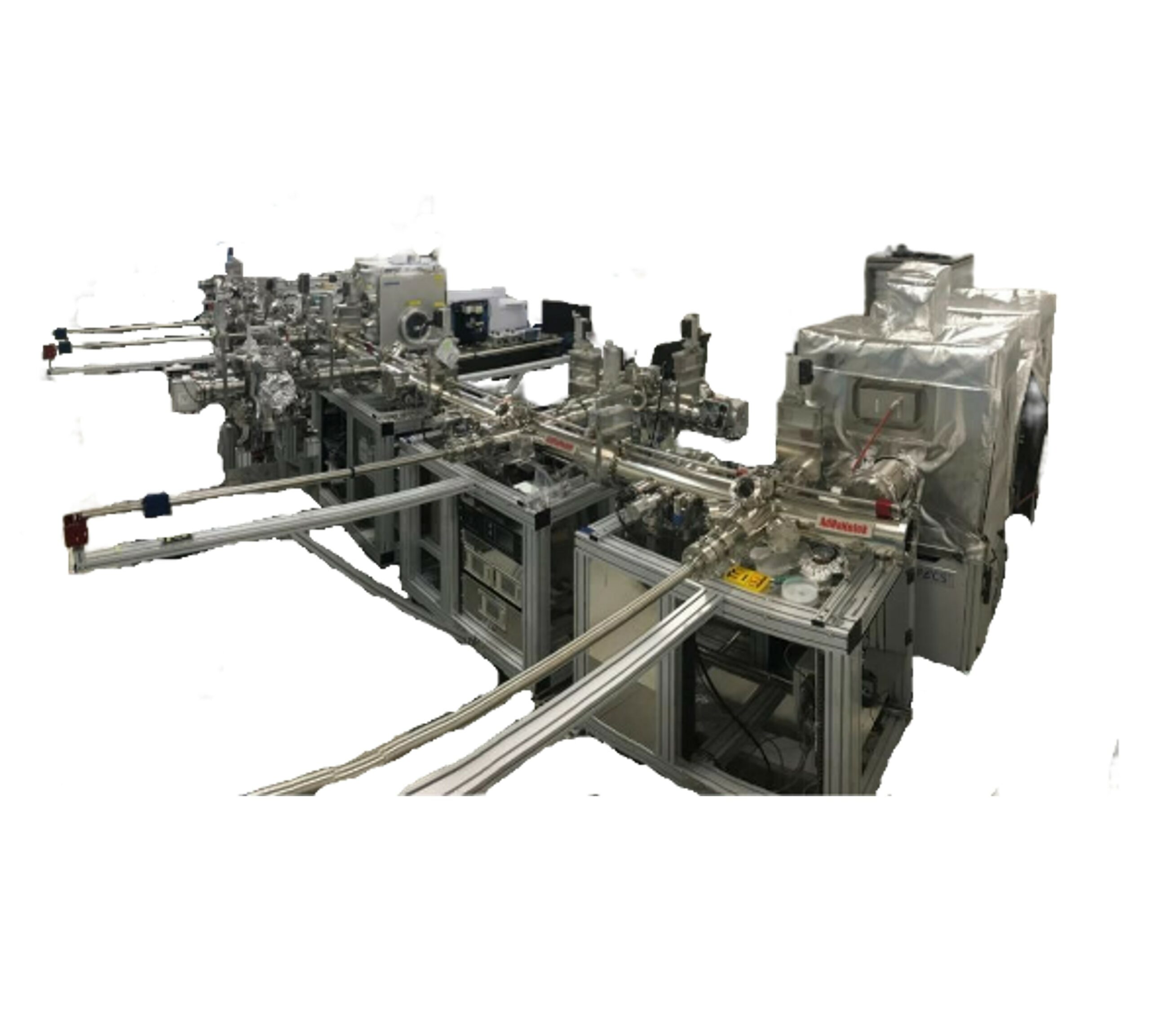

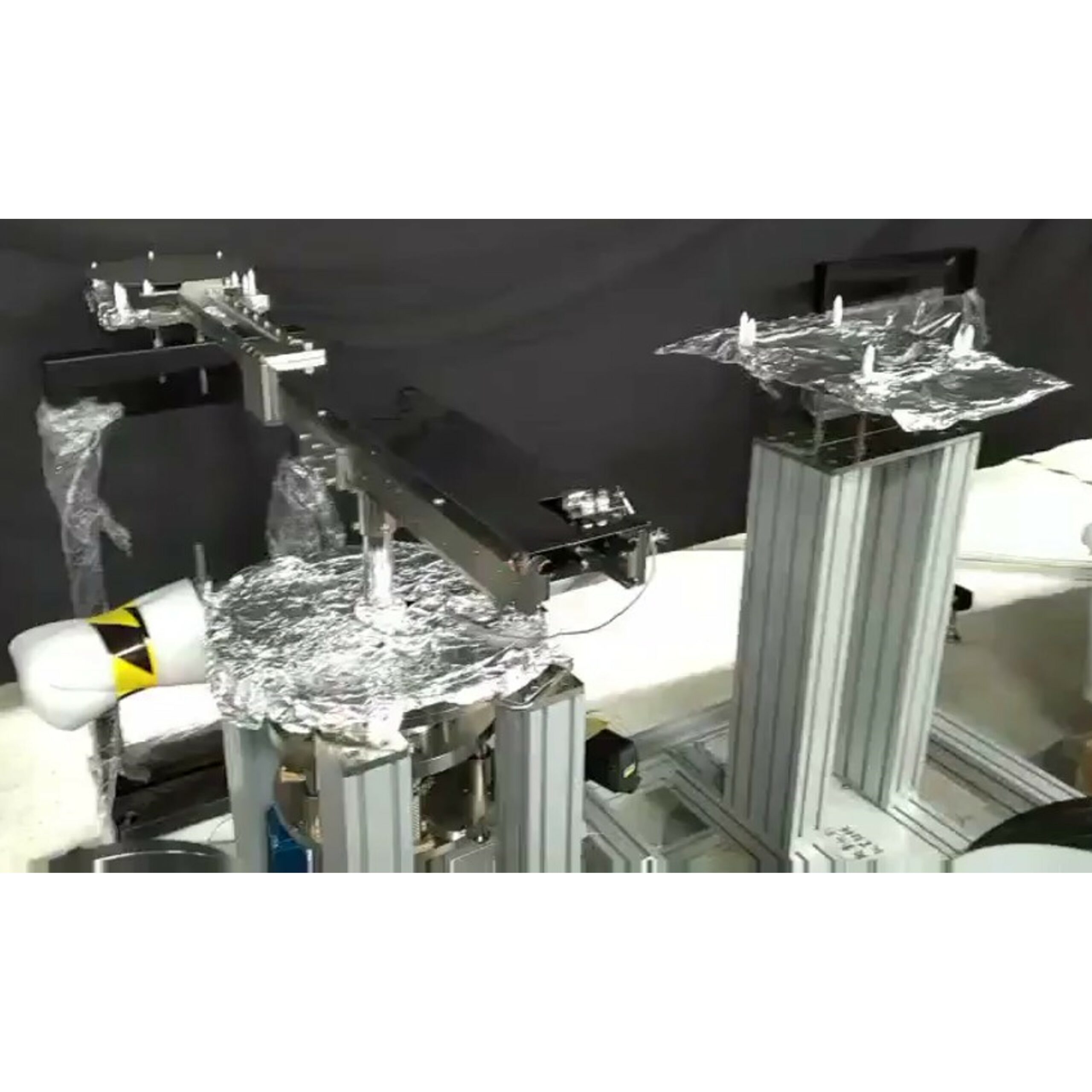

Linear and Cluster system

Linear Transfer System provide substrate move to different sub-station for different process and analysis without break vacuum.

Automatic Transfer arm

Automatic Transfer arm provide substrate move to different chamber for different process without break vacuum.

UHV Transfer Robot

Automatic Transfer robot provide substrate move to different chamber for different process without break vacuum. It can hold up to 12 inch wafer

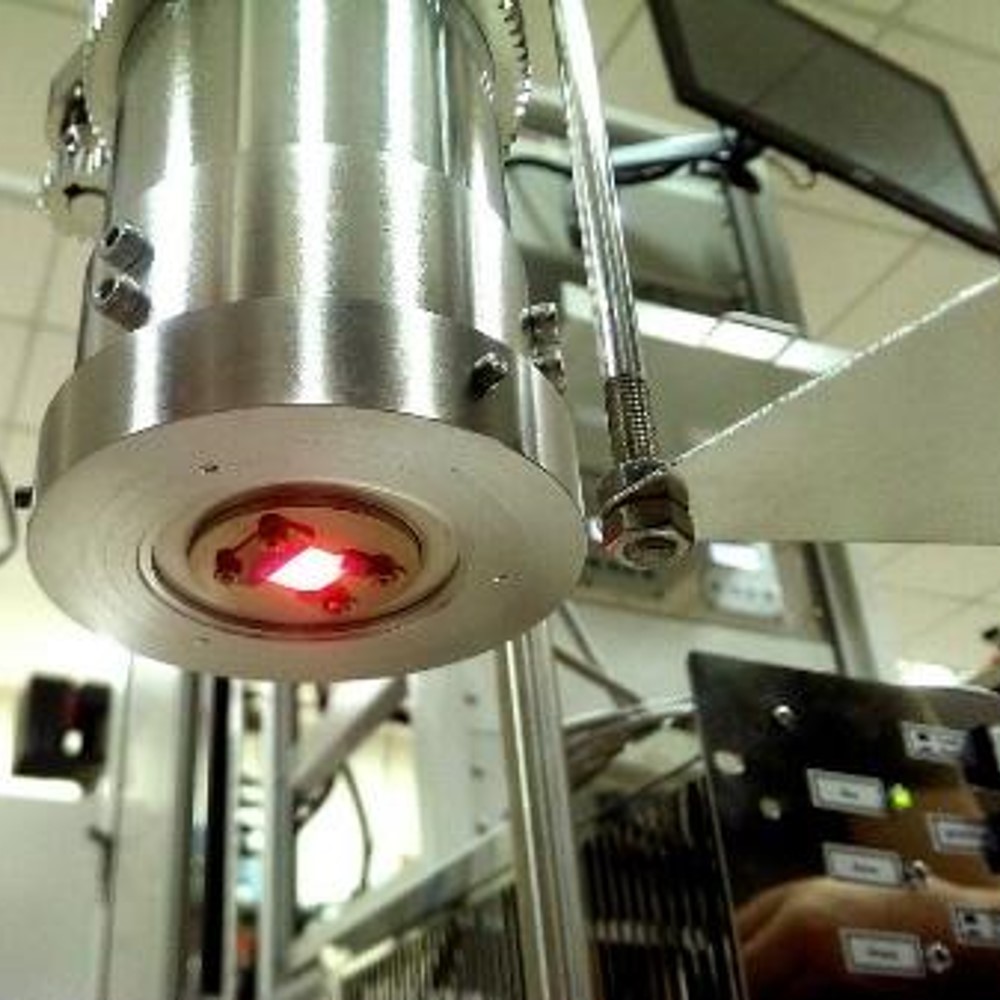

Laser Heater Manipulator

Laser heater provide substrate working condition up to 1000 degree C in Oxygen rich condition, no matter in air and Ozone, our laser heater works well.

We Employ Latest Research Technology & Company

Why People Trust Us

AdNaNoTek Corporation is the rising leader in ultrahigh vacuum (UHV) technologies and solutions provider in the world.

We specialize in the design and manufacture of state-of-the-art and fully customizable UHV systems which fits any research and industrial needs.

JEB-4 has 4 chambers, a) load lock chamber, b) ion beam etching chamber, c) main electron beam or MBE evaporator chamber, and d) oxidation chamber.

High Quality Technology

Unmatched Expertise

Fully Customizable

State-Of-The-Art

Your best partner

AdNaNoTek Corporation is the rising leader in ultrahigh vacuum (UHV) technologies and solutions provider in the world.

Let us know what you need