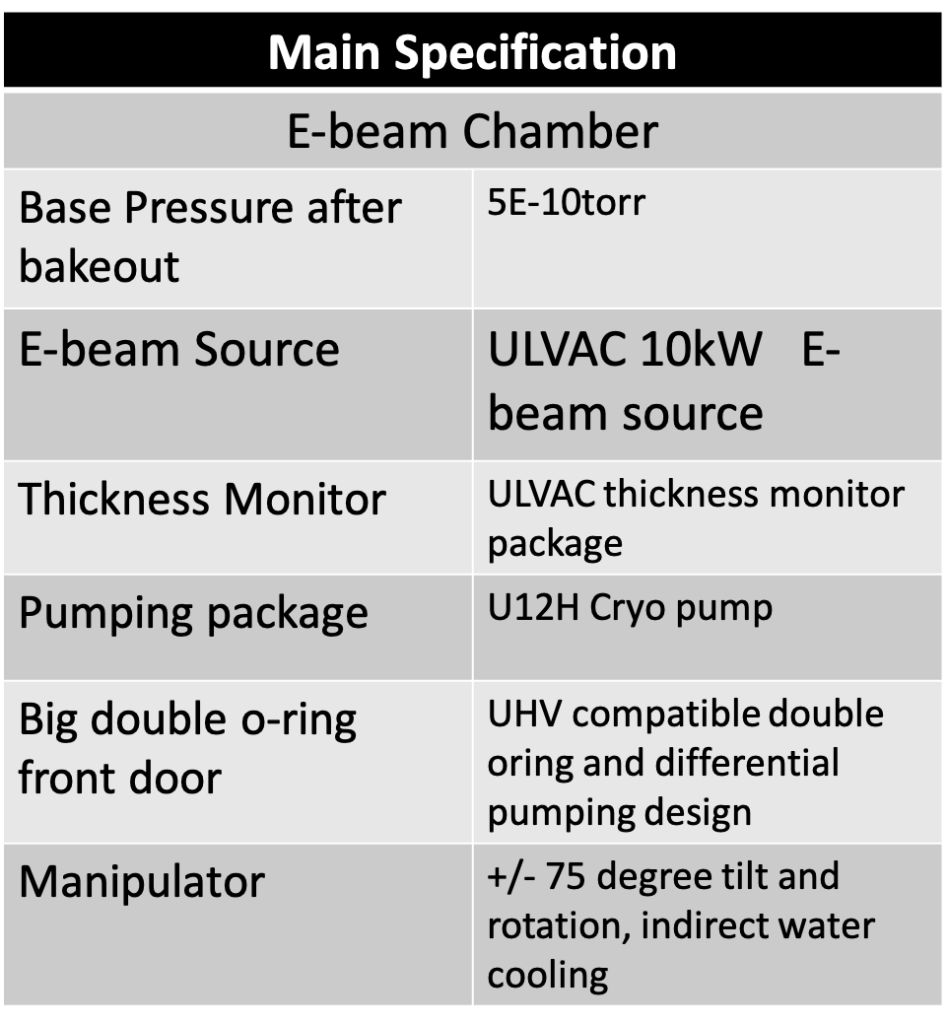

Quantum Computing Deposition System

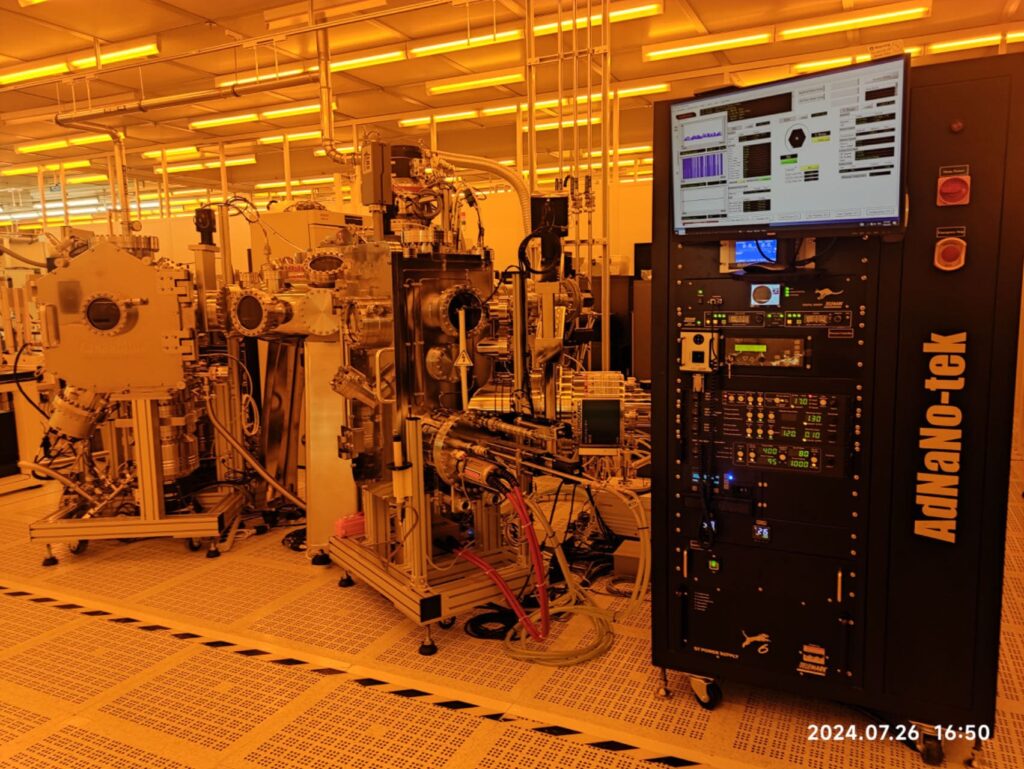

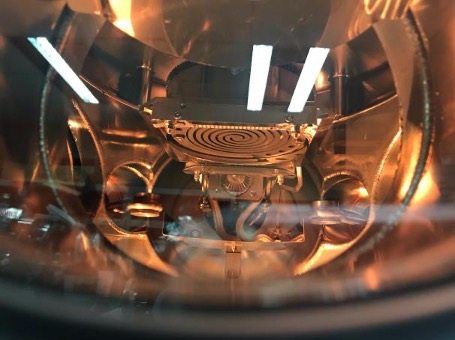

Basic design of Josephson Junction deposition system platform developed by Adnanotek consists of two chambers

– one is for e-beam deposition in UHV and another is used for sample loading and thickness monitor replacement.

Both chambers have independent pumping systems thus providing UHV vacuum conditions

in deposition chamber and fast loading/unloading procedure.

– one is for e-beam deposition in UHV and another is used for sample loading and thickness monitor replacement.

Both chambers have independent pumping systems thus providing UHV vacuum conditions

in deposition chamber and fast loading/unloading procedure.

Categories

Menu

JEB - 2

Quantum Computering

JEB - 3

Quantum Computering

JEB - 4

Quantum Computering

JEB-Diamond

Quantum Computering

This is JEB diamond josephson junction evaporator installed in A star Singapore

Advantages

- Electron beam heating can reach temperatures higher than traditional filament resistance heater. It can heat the target above 3000 °C

- Crucibles with target materials are placed inside cooling slots thus providing evaporation process takes place in close vicinity to electron beam.

Water cooling slots are also necessary to avoid extensive target outgassing during evaporation thus increasing deposited materials quality.

- Electron beam can heat the target surface directly to improve the heating efficiency.

- Crucibles with target materials are placed inside cooling slots thus providing evaporation process takes place in close vicinity to electron beam.

Water cooling slots are also necessary to avoid extensive target outgassing during evaporation thus increasing deposited materials quality.

- Electron beam can heat the target surface directly to improve the heating efficiency.

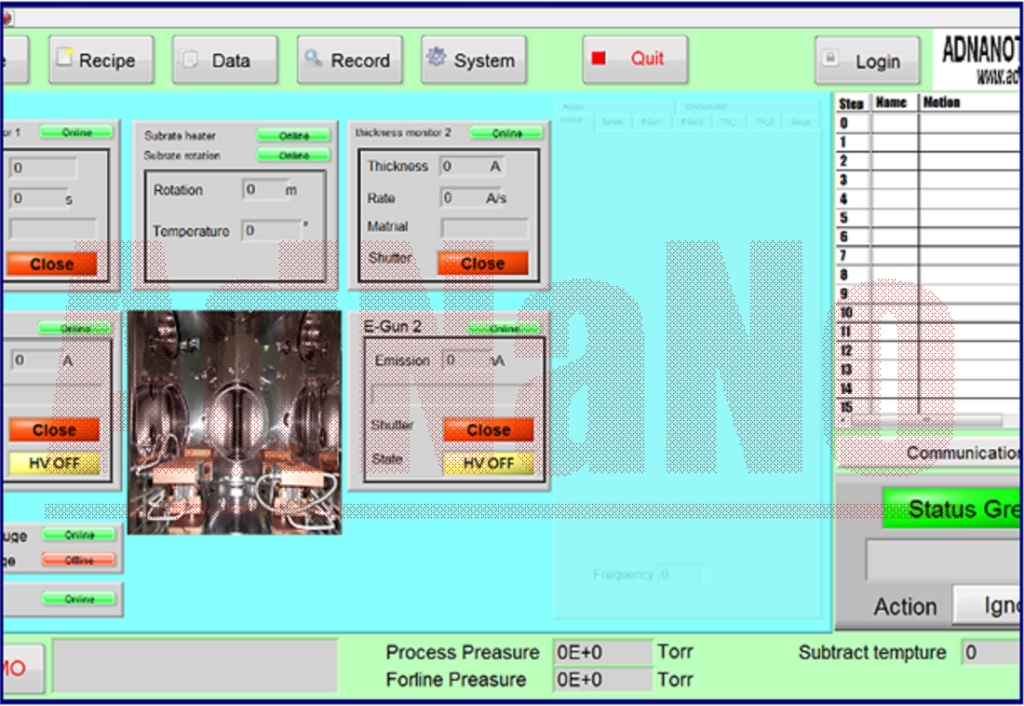

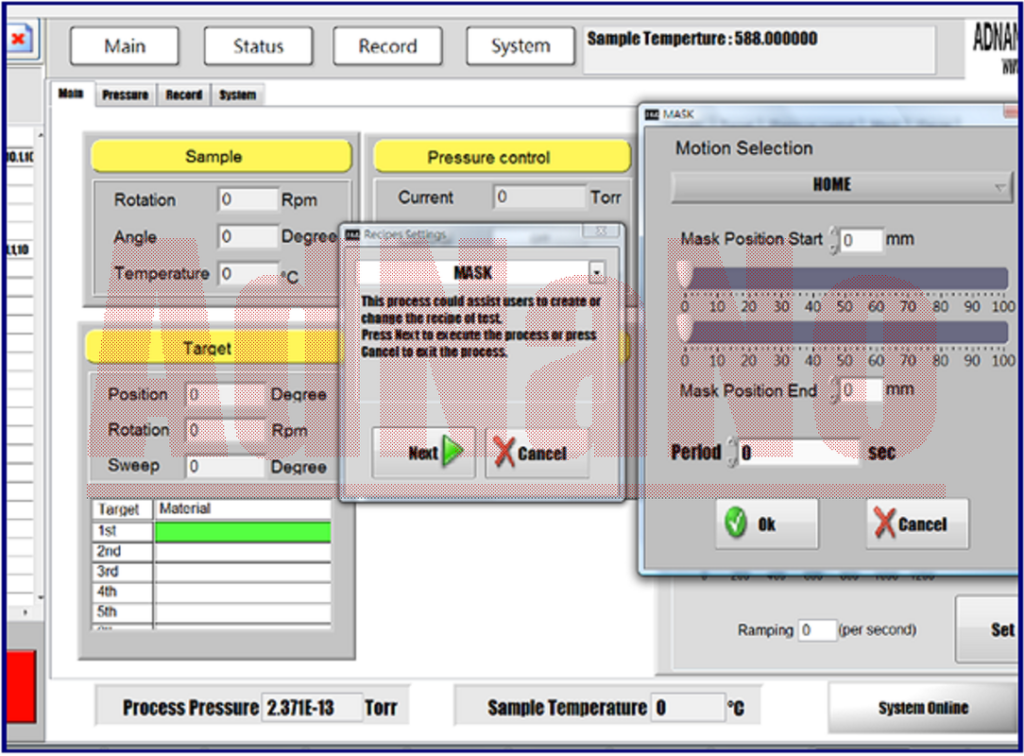

System control software

FBBEAR software is a multi-functional software to control the whole Dual E-Beam system, i.e. Manipulator rotation speed, heating program, target revolution, etc.

FBBEAR can control EUROTHERMO2408 to control, tune and save multi-PID parameters for laser/filament heater for the best accuracy of different substrate temperature requirements.

FBBEAR’s Deposition wizard make it hassle free to set, customize and save your experimental recipe and fully automatize the deposition processes. This also allows easy repetition of the deposition process having same experimental parameters. In addition, it also allows recording of data log in order to review past deposition parameters.

FBBear can do data processing and analysis.

FBBEAR can control EUROTHERMO2408 to control, tune and save multi-PID parameters for laser/filament heater for the best accuracy of different substrate temperature requirements.

FBBEAR’s Deposition wizard make it hassle free to set, customize and save your experimental recipe and fully automatize the deposition processes. This also allows easy repetition of the deposition process having same experimental parameters. In addition, it also allows recording of data log in order to review past deposition parameters.

FBBear can do data processing and analysis.

Customer’s result

E beam Manipulator

SiC Heater, Rotation and Tilt Water Cooling

Ion Milling Chamber

Manipulator, Rotation and Tilt Water Cooling

JEB Manipulator

Possibilities for heating

Laser Heater for Laser annealing

Can be installed in JEB-4 Loadlock chamber to provide high temperature anealing (over 1000 degreeC) process

Can be installed in JEB-4 Loadlock chamber to provide high temperature anealing (over 1000 degreeC) process

SIC Heater

Can be installed in Oxidation chamber to provide high temperature oxidation process (800 degreeC)

Can be installed in Oxidation chamber to provide high temperature oxidation process (800 degreeC)

JEB - ADV

This JEB-2 is 3 chambers design include a standard load lock chamber, UHV sputter deposition chamber and E-beam source under sputter chamber, Sputter chamber include Oxidation and milling and sputter process.