Molecular Beam Epitaxy (MBE)

AdNaNoTek offers advanced Molecular Beam Epitaxy (MBE) for atomic-layer precision. Achieve high-quality epitaxial thin films with precise control, ideal for III-V and emerging materials.

Categories

Menu

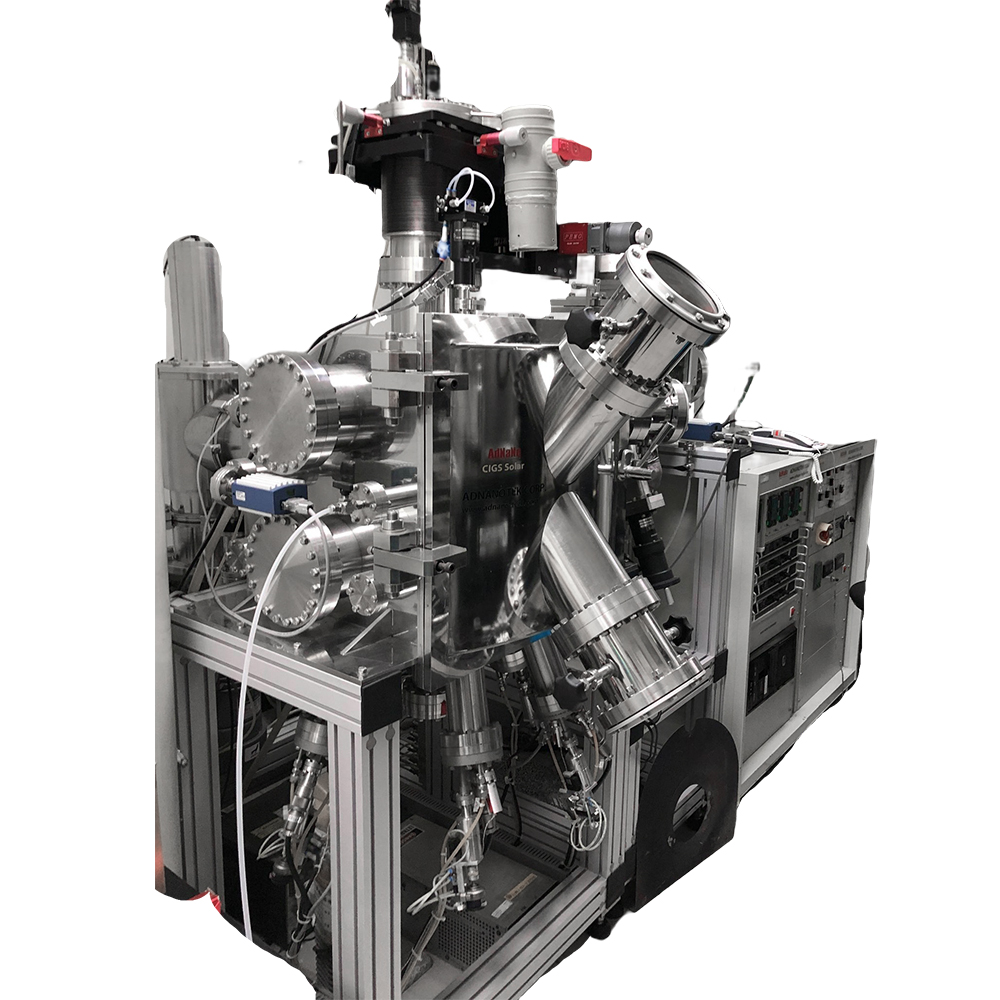

MBE - 6

Molecular Beam Epitaxy

MBE - 9

Molecular Beam Epitaxy

MBE - 10

Molecular Beam Epitaxy

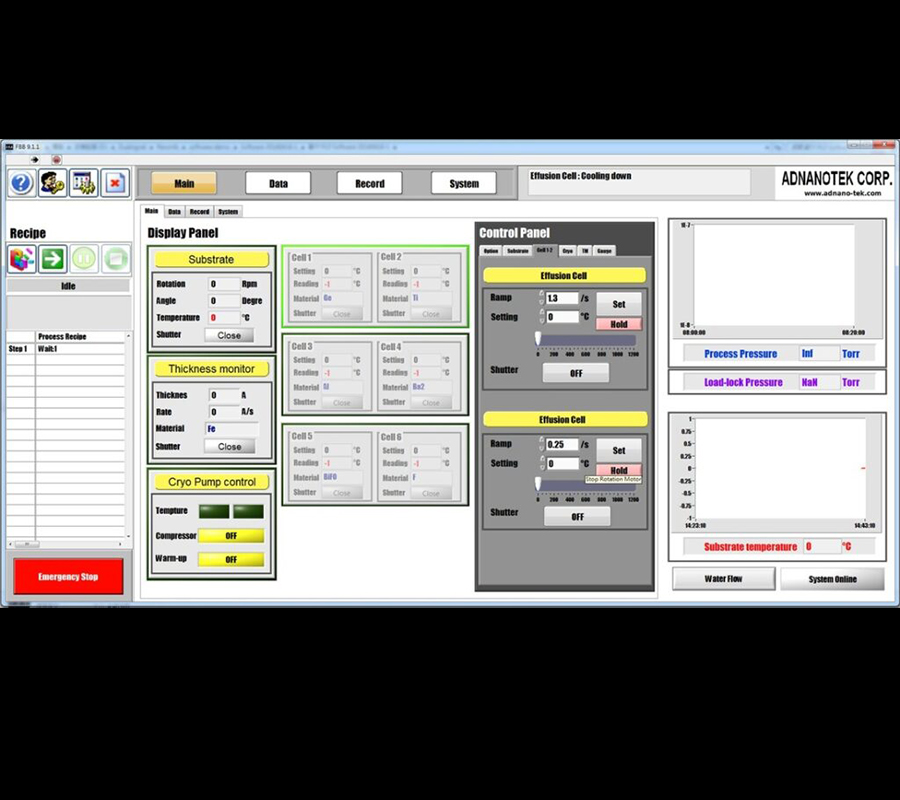

MBE - Control Software

Molecular Beam Epitaxy

Adnano-tek MBE system is easy use with a design configurable for III-V and emerging materials, including applications that require the integration of e-beam technology.

Our design allows linear transfer system for different coating and analysis.

Our design allows linear transfer system for different coating and analysis.

Servies

- Ideal for materials research and pre-production environments

- Source to substrate orientation with 8 MBE solid source and 6 ALD source ports and the option to add e-beam capabilities

- Manual or automated wafer transfer options

- Cryopanel, manipulator, shutters and in-situ monitoring equipment

- Modular design

Molecular Beam Epitaxy (MBE) is an ultrahigh vacuum (UHV) deposition technique used for producing high quality epitaxial (atomic layer) thin film with precise control on thickness, composition and morphology.

This allows MBE technique to produce much higher thin layer quality compared to non-UHV-based techniques.

This allows MBE technique to produce much higher thin layer quality compared to non-UHV-based techniques.

In MBE, the target material in the effusion cell is carefully heated to increase its vapor pressure.

At UHV conditions (E-9 torr) the vapor can travel towards the substrate without collision, where it can condense on the substrate to form epitaxial thin layer film with high level of purity.

At UHV conditions (E-9 torr) the vapor can travel towards the substrate without collision, where it can condense on the substrate to form epitaxial thin layer film with high level of purity.

Despite the conceptual simplicity, a great technological effort is required to produce a system that yield desired thin-layer film qualities.

The chamber design, careful control of vacuum environment, the quality of the source materials, the evaporation process, sample handling mechanisms, and over-all architecture needs to be designed with great precision in order to achieve high level of purity, uniformity, interface control in the deposited thin-layer film.

AdNaNoTek's MBE System is designed satisfying all those requirements.

In addition, AdNaNoTek's FBBear system control software allows user to fully automate the deposition process and precisely control each parameters to achieve high quality thin-films.

In addition, AdNaNoTek's FBBear system control software allows user to fully automate the deposition process and precisely control each parameters to achieve high quality thin-films.

Our long-term cooperation with our customers greatly expanded our MBE technology by developing different molecular sources and adapting to different coating deposition requirements.

In MBE conference, It is so honor to take photo with Dr. Alfred Y. Cho the father of MBE technology.

We have shortly discuss some epi news.

We have shortly discuss some epi news.

Dr. Alfred Y. Cho -

The Father of MBE Technology

The Father of MBE Technology