Laser Direct Writer

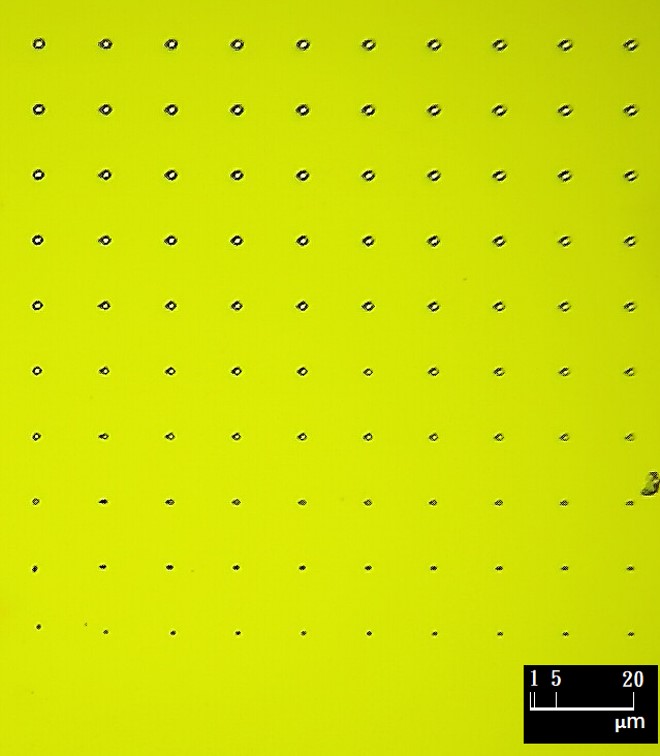

Laser direct writer is one of the main technologies for making diffractive optical elements. It uses a laser beam with variable intensity to perform variable dose exposure to the resist material on the surface of the substrate.

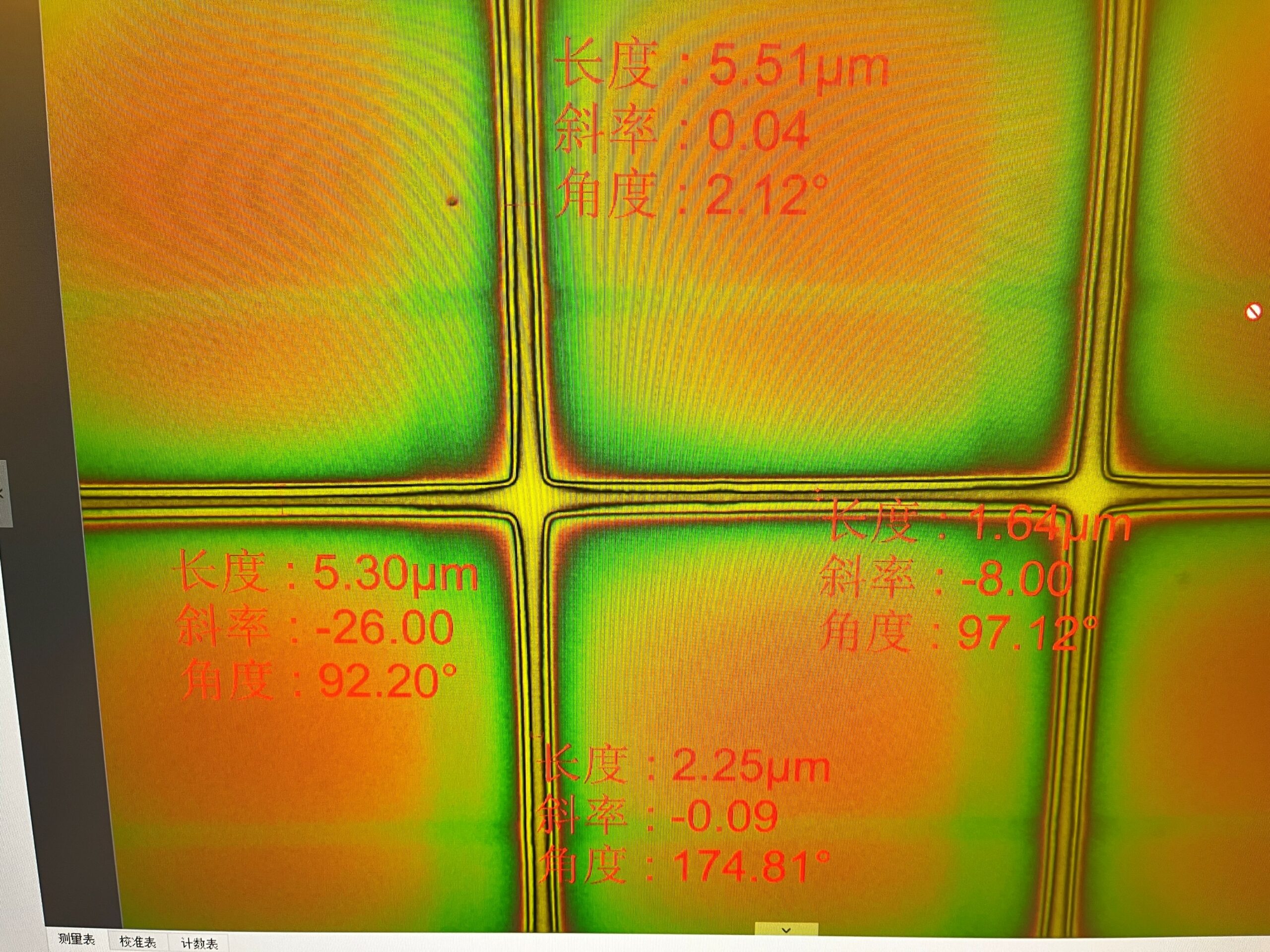

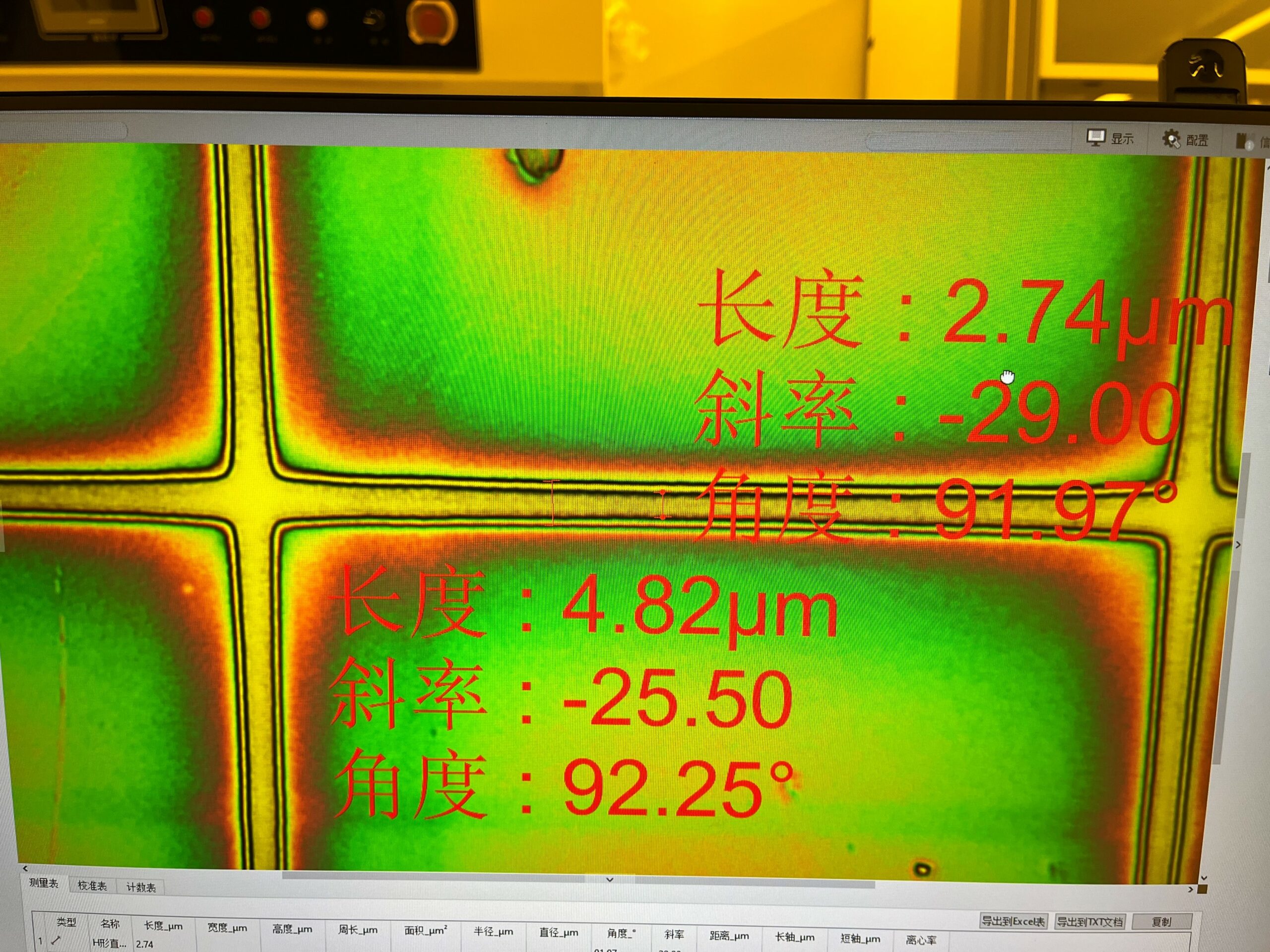

After development, the required relief profile is formed on the surface of the resist layer. The fabrication precision can reach the sub-micron level.

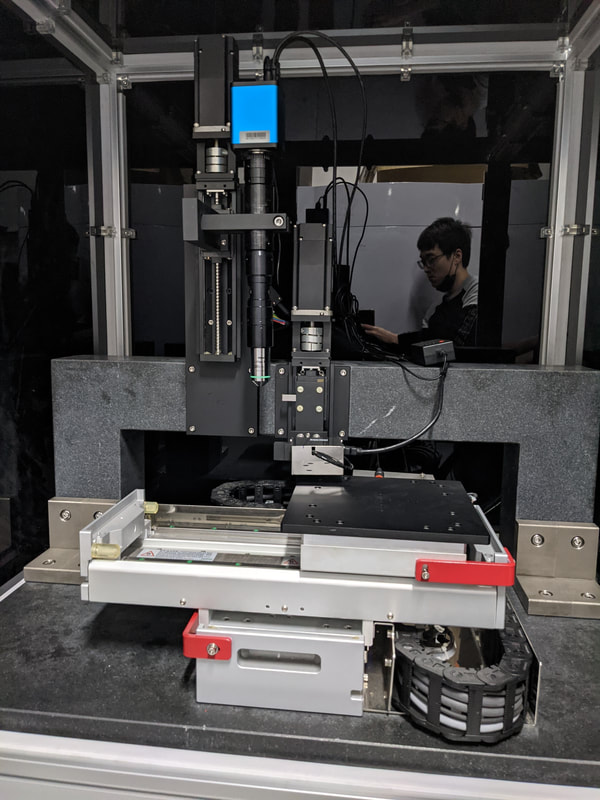

Direct Laser Writer developed by Adnanotek would significantly reduce cost and time of any pattern fabrication on the wafer.

With the help of an easy to use GUI a desired pattern could be generated and transferred on the sample surface.

Key features include:

- Maximum surface area:20x20 cm2

- Laser wavelength:405 nm

- Lateral resolution1 - 5 μm (depending on pattern complexity and photoresist properties)