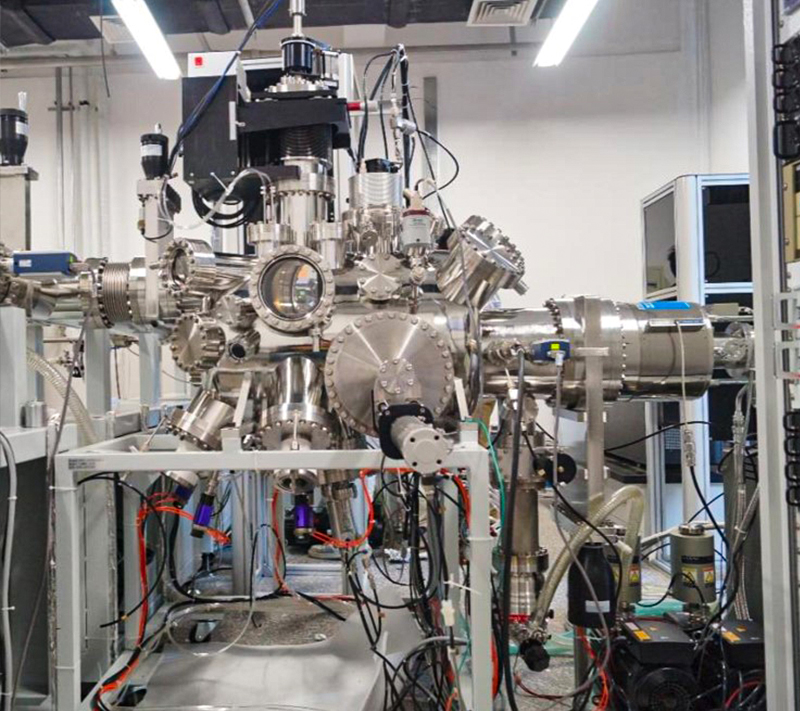

AdNaNoTek’s IBSD

Ion-Beam Sputter Deposition (IBSD) is a thin-layer deposition method in which the mechanism of ion production is separate from the target.

The ion source generate ions from a hot filament by collisions with electrons that are confined by a magnetic field.

The ions are then accelerated toward the target material by an electric field from a grid. As the ions leave the ion source they can be (depending on the design) neutralized by electrons from a second external filament.

The ions/neutral atom will then strike the atoms on the surface of the target thus removing target atoms by momentum transfer.

These atoms are then condensed onto the substrate as a thin film.

The ion source generate ions from a hot filament by collisions with electrons that are confined by a magnetic field.

The ions are then accelerated toward the target material by an electric field from a grid. As the ions leave the ion source they can be (depending on the design) neutralized by electrons from a second external filament.

The ions/neutral atom will then strike the atoms on the surface of the target thus removing target atoms by momentum transfer.

These atoms are then condensed onto the substrate as a thin film.

The advantage of IBSD is that the energy and flux of ions can be controlled and measured independently.

Since the ion beam current can be monitored during the deposition process, this parameter can serve as a quantitative measure for the deposited amount of material.

Also, since the flux that strikes the target is composed of neutral atoms, either insulating or conducting targets can be sputtered.

AdNaNoTek's IBSD system is designed to maintain UHV conditions, also the sample handling and over-all design are precisely calculated to ensure deposition of high quality films.

AdNaNoTek's FBBear Control Software makes IBSD operation reliable and hassle-free. In addition, our vast-experience and long-term cooperation with our customers continuously improve and optimize our systems.

Since the ion beam current can be monitored during the deposition process, this parameter can serve as a quantitative measure for the deposited amount of material.

Also, since the flux that strikes the target is composed of neutral atoms, either insulating or conducting targets can be sputtered.

AdNaNoTek's IBSD system is designed to maintain UHV conditions, also the sample handling and over-all design are precisely calculated to ensure deposition of high quality films.

AdNaNoTek's FBBear Control Software makes IBSD operation reliable and hassle-free. In addition, our vast-experience and long-term cooperation with our customers continuously improve and optimize our systems.

AdNaNoTek’s Ion Beam Sputtering Deposition (IBSD) can deposit large-scale thin-film with extremely high quality and a great repeatability.

IBSD utilizes ion source to generate a focused ion beam directed at the target to be sputtered.

Since the target material is ablated by momentum transfer rather than a chemical or thermal process, any material can be deposited on the substrate (whether it is conductor, or insulator).

IBSD utilizes ion source to generate a focused ion beam directed at the target to be sputtered.

Since the target material is ablated by momentum transfer rather than a chemical or thermal process, any material can be deposited on the substrate (whether it is conductor, or insulator).

Target holders are designed to have multiple faces that allows deposition of different targets by means of rotation.

In addition, ion beam assisted sputtering source is included that allows gradual transition between the substrate material and the deposited film, by reducing crystal strain.

And, together with the mask system, this will allow formation of unique deposition pattern on the thin film.

In addition, ion beam assisted sputtering source is included that allows gradual transition between the substrate material and the deposited film, by reducing crystal strain.

And, together with the mask system, this will allow formation of unique deposition pattern on the thin film.

Main Specifications

- Custom-type SS316L electro-polished chamber

- 5E-7 Torr Base Pressure

- Vacuum pumps and gauges

- 4-in substrate

- 4-axes sample manipulator (XYZ, and Rotation)

- Water cooling manipulator

- Ion Beam Deposition and assist Source (Gridded - RFICP / KDC; or Gridless - EH)

- 4 Sputter cathodes

- Cube-type target assembly

- Thickness monitor

- FBBeam System Control Software

Optional

- O2 or N2 plasma source

- Ion beam assisted deposition system

- Pre-annealing heating system in Load Lock

- Chamber designs are customizable

- Sputter Cathodes

Major Applications

- High quality film

- Low background pressure

- Control of beam energy, current, species, and incident angle

- All parameters can be control almost independently in a wide range

- Congruent evaporation

- Versatile method (any material)

System Control Software

FBBEAR software is a multi-functional software to control the whole IBSD - 20 system, i.e. Manipulator rotation speed, heating program, target revolution, etc.

FBBEAR can control EUROTHERMO2408 to control, tune and save multi-PID parameters for laser/filament heater for the best accuracy of different substrate temperature requirements.

FBBEAR’s Deposition wizard make it hassle free to set, customize and save your experimental recipe and fully automatize the deposition processes.

This also allows easy repetition of the deposition process having same experimental parameters. In addition, it also allows recording of data log in order to review past deposition parameters.

FBBear can do data processing and analysis.

FBBEAR can control EUROTHERMO2408 to control, tune and save multi-PID parameters for laser/filament heater for the best accuracy of different substrate temperature requirements.

FBBEAR’s Deposition wizard make it hassle free to set, customize and save your experimental recipe and fully automatize the deposition processes.

This also allows easy repetition of the deposition process having same experimental parameters. In addition, it also allows recording of data log in order to review past deposition parameters.

FBBear can do data processing and analysis.