Laser Heating

Categories

Menu

Triditional heater cannot survivir in oxygen condition because the heater element is very active in high temperature, it is easy to be broken during usage.

We used different way, adnano-tek provide you ultimate solution. Based on our technology there is no heater element inside chamber; so there is no easy damage parts in the chamber.

The laser device is inside controller with cooling device very long life and high heating performance, and only subtracts are in hot zone rest part of chamber rather cool.

We used different way, adnano-tek provide you ultimate solution. Based on our technology there is no heater element inside chamber; so there is no easy damage parts in the chamber.

The laser device is inside controller with cooling device very long life and high heating performance, and only subtracts are in hot zone rest part of chamber rather cool.

Heater damage when heat up subtracts under oxygen or ozone condition?

Replace Adnano-Tek Laser Heater for PLD and Oxide MBE.

Neocera poineer pld upgrade to Adnano-Tek Laser Heater.

Do you have heating problem in oxygen? Leave this problem to adnano-tek.

In this case, our customer having a damaged pld because manipulator heater filament broken, we solve this problem by replacement our laser heater, and the best part is neocera software is functional and competible with adnano-tek laser heater.

Now, the pld is easy heating up to 1000 degree in any oxygen condition in vacuum; and it is real "laser mbe".

Please contact us for replacement your old heater; it is easy and you can install this laser heater by yourself!

In this case, our customer having a damaged pld because manipulator heater filament broken, we solve this problem by replacement our laser heater, and the best part is neocera software is functional and competible with adnano-tek laser heater.

Now, the pld is easy heating up to 1000 degree in any oxygen condition in vacuum; and it is real "laser mbe".

Please contact us for replacement your old heater; it is easy and you can install this laser heater by yourself!

Main Specifications

- Laser power: 70W-200W (different model)

- Substrate size: 10x10 mm2 (up to 6-inch diameter)

- Up To 2 Or 4 Inch Diameter Sample Laser Heater

-

Heating temperature 1200°C (E-3 torr and below) or 1000°C (above 760torr)

Fully compatible to oxygen-rich or any atmospheric condition - ±1°C temperature stability

- PID temperature control

- XYZ axis movements

- 360° continuous rotation

- 5° substrate tilt

- Fan and Water cooling system

- Pneumatic substrate shutter

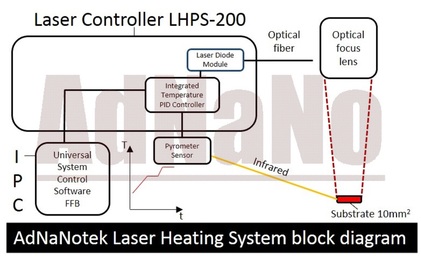

- Real-time temperature monitor by pyrometer (single wavelength, can monitor > 260°C)

- State-of-the-art and easy operation computer software control

- For high temperature applications

- For Oxide-, or any atmospheric condition applications

- Compatible with all UHV systems

- Optical fiber

- Focusing lens with adjustable support

- Infrared pyrometer for temperature monitoring (with adjustable support)

- PID temperature control

- RS232 communication port for remote controlling

- Control software for real time temperature monitoring, controlling, and alarm

Advantages

-

Heating temperature 1200°C (E-3 torr and below) or 1000°C (above E-3 torr)

Fully compatible to oxygen-rich or any atmospheric condition - No heating components adds in vapor pressure in the chamber

- Localized heated area, lesser out-gassing during heating (you can deposit with a cleaner condition)

- 5° substrate tilt

- Easier maintenance compare to traditional substrate heater (the heating element is outside of the vacuum)

- Direct temperature measurement from sample/substrate by pyrometer

Options

- Liquid nitrogen cooling

- Customizable manipulator

- Pulsed heating mode

Designing a high temperature heater for UHV thin-film deposition systems which can work in oxygen-rich or any atmospheric conditions is not easy.

Conventional heating materials and mechanisms generate additional vapor pressure from its heating component materials which limits the achievable UHV condition, and oxidize its heating components which consequently deteriorate the heating material and process quality.

There are some techniques to overcome this problem, such as Platinum heating element, SiC heating element with well-designed shape, etc. However, each methods has their own issues, such as high maintenance frequency, short life time due to oxidation of heating components, etc.

Conventional heating materials and mechanisms generate additional vapor pressure from its heating component materials which limits the achievable UHV condition, and oxidize its heating components which consequently deteriorate the heating material and process quality.

There are some techniques to overcome this problem, such as Platinum heating element, SiC heating element with well-designed shape, etc. However, each methods has their own issues, such as high maintenance frequency, short life time due to oxidation of heating components, etc.

AdNaNoTek's Laser heating manipulator is developed as a perfect solution for heating your sample for UHV thin-layer deposition in oxygen-rich and any atmospheric conditions. It does not possess the disadvantages that other heaters have.

In addition, it is easy-to-use, compact, customizable, and has fast and localized heating mechanism. It is equipped with a pyrometer to monitor the temperature, and has a system control software to automatically control the laser heating parameters and processes.

AdNaNoTek's Laser Heating Manipulator is very suitable for laser oxide/nitride epitaxial techniques.

In addition, it is easy-to-use, compact, customizable, and has fast and localized heating mechanism. It is equipped with a pyrometer to monitor the temperature, and has a system control software to automatically control the laser heating parameters and processes.

AdNaNoTek's Laser Heating Manipulator is very suitable for laser oxide/nitride epitaxial techniques.

Video